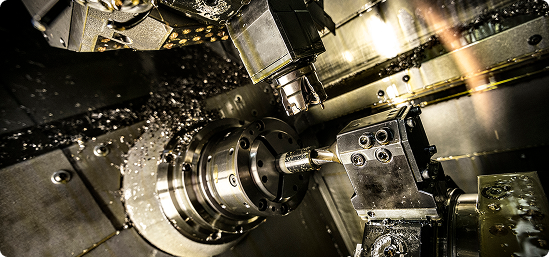

CNC machining can be an unforgiving process. Errors, collisions, lost time, and lost efficiency can all have challenging outcomes.

The biggest challenge of all? Your machines not producing parts.

Machine crashes, in particular, are disastrous for machine shops. They cost thousands of dollars to repair, keep high-end equipment idle, and disrupt production schedules.

At the same time, verifying jobs manually is damaging to your bottom line. When your people and your machines are occupied proving out jobs, they’re not being used to produce parts.

Collisions, scrap, extra setup, and prove-out time all directly impact profitability. Lost productivity and higher costs don’t just reduce efficiency — they limit your shop’s ability to stay competitive in an industry where uptime is everything.

Fixing CNC machine inefficiency with the right tools

Gambling on programming errors with a trial-and-error approach just won’t cut it in 2025.

The complexity of today’s multi-axis machining, tighter tolerances, and rising cost pressures mean manufacturers need better ways to safeguard productivity.

The solution? Powerful CNC machine simulation and verification software.

By introducing a digital proving ground into your workflow, you give engineers and machinists the ability to catch mistakes before they ever reach the shop floor.

Instead of testing processes on real machines, risking expensive equipment and precious time, simulation shifts testing and validation into the virtual world.

Benefit of machine simulation: Error-free machining

Software-based machine simulation, like Vericut Verification, essentially acts as a virtual proving ground for your CAD/CAM processes. This allows your engineers and machinists to stop errors and collisions before your tools begin to work in real life.

What advanced collision checking can you expect from machine simulation?

- Checks on the entire setup and toolpath

- Full range of motion inside the machine

- Tool-to-part collisions

- Tool-to-fixture collisions

- Clashes between machine components

Any one of these errors can be disastrous. Machine simulation eliminates the risk, making near misses a thing of the past.

What sets Vericut apart is its ability to verify the actual G-code line by line. This means programmers can be alerted to issues in the exact code that will run on the machine — no approximations, no guesswork.

For complex multi-axis sequences in particular, this level of detail ensures errors are caught before real damage is done.

The benefit for your business is simple: no more manual prove-outs, no more gambling with downtime, and no more expensive mistakes.

Taking manual prove outs off the shop floor

How much time does your team spend each year proving out jobs? And more importantly, what does that equate to in lost revenue?

With simulation, prove-outs no longer take place on the shop floor. Processes are tested, refined, and perfected in software before they ever reach the machine.

When the program is finally loaded onto the CNC, operators can confidently run it at full speed.

The result?

- More machine uptime

- Shorter lead times

- Operators freed up for higher-value work

- Smoother schedules with fewer last-minute interruptions

Benefit of machine simulation: Efficiency gains through optimization

Beyond avoiding costly errors, machine simulation gives manufacturers a powerful route to higher output, better tooling efficiency, and reduced waste.

Vericut Force does this by moving trial-and-error away from your machine and into a digital environment, allowing engineers to fine-tune paths, cutting forces, and feeds and speeds before a job starts in earnest.

Using Vericut Force, manufacturers can use powerful machine learning to find hidden routes to efficiency. The results are transformative for manufacturers and finance leaders: faster cycle times and longer tool life.

his isn’t just theory. Manufacturers around the world are seeing real, measurable results:

Discover real-world results:

- Sandvik-Gimo save 15.3% energy per workpiece and €3,000 per machine per year with Vericut Force

- AML boosts tool life by 40% with Vericut Force

- Imflux cuy ctyle times by up to 51% with Vericut Force

Benefit of machine simulation: Financial gains

It’s easy to think of simulation as a tool for engineers alone, but its impact resonates across the business.

Finance teams appreciate that reducing crashes lowers repair bills, extending tool life cuts consumable costs, and shaving seconds off cycle times adds up to significant annual savings.

By framing simulation as both a risk management tool and a profit driver, manufacturers can justify investment in software as an enabler of long-term competitiveness.

Benefit of machine simulation: Skill gains

Beyond protecting machines and boosting profitability, simulation also empowers people.

When operators know their jobs have been thoroughly verified, they can confidently run programs instead of cautiously. This reduces stress on the shop floor, improves focus, and allows teams to shift their energy from fire-fighting to fine-tuning processes.

For newer machinists, simulation acts as an educational tool, showing how toolpaths behave in real-world conditions without the fear of crashing a machine.

This accelerates training, reduces onboarding time, and helps build a stronger, more capable workforce. In a time when skilled machinists are in short supply, giving teams tools that both protect them and enhance their learning is a competitive advantage in its own right.

What’s next for machine simulation?

Manufacturers will always push for greater speed, precision, and process security, and AI will certainly lead this charge.

Launching on the next major Vericut Product release, Vericut have two new AI tools to kickstart your journey in AI-driven machine simulation tools:

Verciut Intelligence is your simple-to-use centralized knowledge resource for all things Vericut. Communicate naturally and find product information in seconds.

Vericut Assistant is being upgraded with AI to ensure users can communicate directly with the software for faster, more efficient use of Vericut features.

The bottom line

Machine simulation isn’t just about preventing crashes. It’s about transforming how shops operate: removing errors, cutting down on wasted time, and opening the door to efficiency gains that drive profitability.

With proven case studies, advanced verification, and the next wave of AI-driven tools, Vericut is helping manufacturers stay one step ahead in an increasingly competitive world.

By moving prove-outs and optimization into the digital realm, you’re not only protecting your machines — you’re future-proofing your entire production process.