Mold and die machining isn’t just another step in manufacturing — it’s the stage where precision defines the future of thousands, sometimes millions, of downstream parts.

Every project is a one-off, often involving hard-to-machine materials and tight deadlines. With little room for trial-and-error, even the smallest error can cascade into costly defects, missed deliveries, or full-scale production shutdowns.

For mold and die professionals, the stakes couldn’t be higher. Complex geometries, deep cavities, and freeform surfaces demand multi-axis CNC machining and long, risk-prone toolpaths.

Tight tolerances, measured in microns, mean even minor imperfections can render a mold unusable. Add to this the pressure of rising tooling costs and immovable deadlines, and the margin for error disappears.

That’s why leading manufacturers around the world trust Vericut CNC simulation software to get it right the first time.

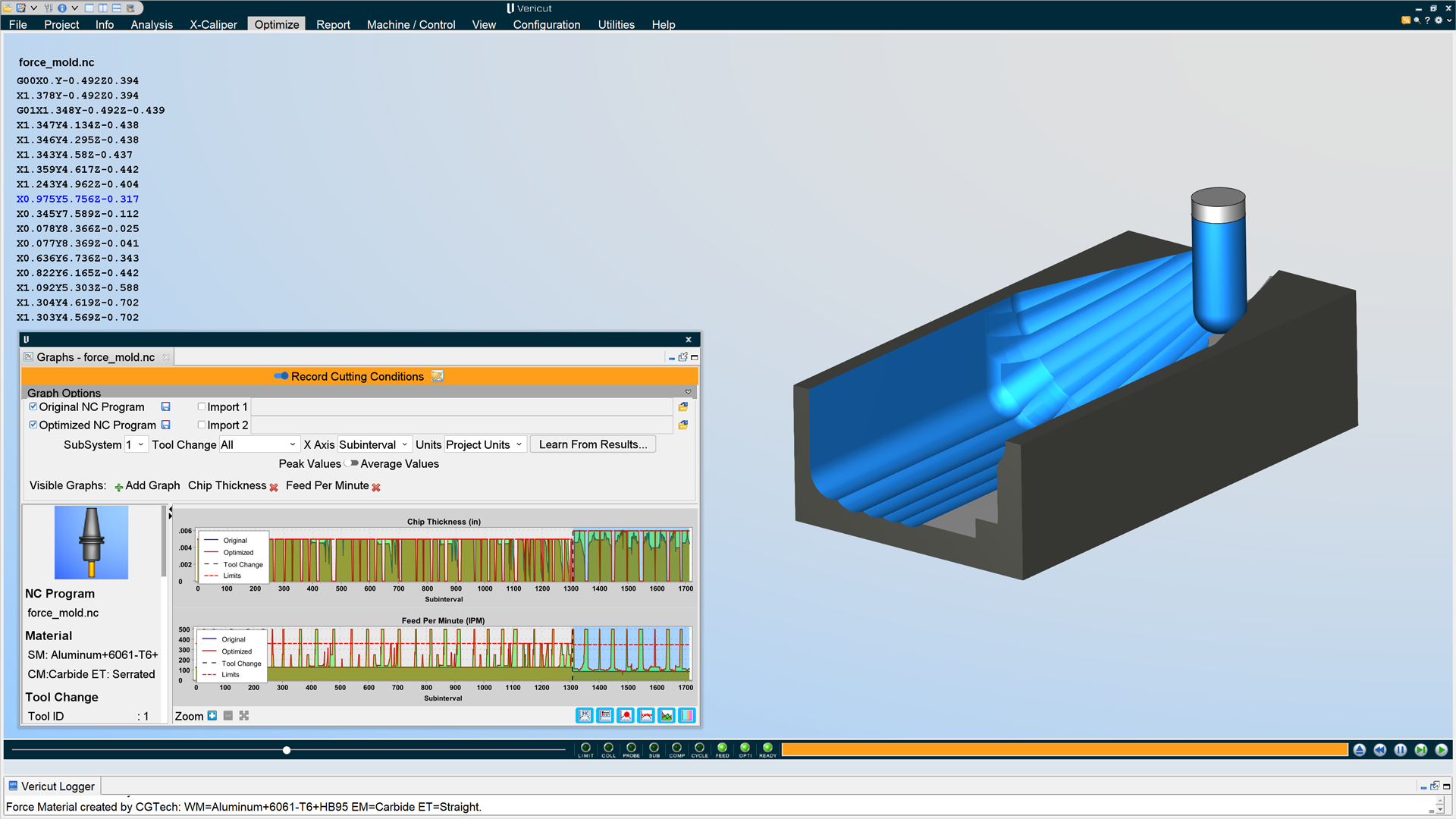

By verifying toolpaths directly from NC code and optimizing machining conditions in advance, Vericut enables shops to deliver molds and dies that are accurate, safe, and production-ready for plastic injection molding and stamping applications.

Undercuts, deep cavities, and freeform surfaces typically demand 5-axis or multi-axis CNC machining, creating long and complex toolpaths that are prone to risk.

Even microns of deviation, or small surface imperfections, can render a mold unusable for use.

Mold and die components aren’t cheap, and when NC programs fail to meet design intent, costly scrap, wasted electrodes, and tool damage quickly build up.

With downstream injection molding or stamping lines waiting, delays can soon ripple across entire production schedules.

-2.png?width=330&height=313&name=Content%20(1)-2.png)

-1.png?width=600&height=313&name=Content%20(2)-1.png)

.png?width=50&height=60&name=shield-check--shield-protection-security-defend-crime-war-cover-check%20(1).png)

-1.png?width=900&height=470&name=Content%20(3)-1.png)

-1.png?width=495&height=470&name=Content%20(4)-1.png)

Many molds require Electrical Discharge Machining (EDM) to finish features unreachable by cutting tools. However, producing and validating electrodes adds cost, complexity, and delivery risk.

Vericut’s Die Sinking EDM simulation closes this gap by validating electrode geometry, checking gouges or remaining material, and ensuring accuracy across every electrode at once.

This is critical because some molds require more than 100 electrodes, meaning manually checking each isn’t just inefficient - it’s error-prone.

With Vericut, shops reduce unnecessary electrodes, cut costs, and deliver molds faster to injection molders who depend on them.

-1.png?width=698&height=465&name=Media%20(1)-1.png)

A high-quality mold sets the standard for thousands of products. That means manufacturers must be certain that each and every mold is built on validated, optimized, and production-ready machining processes.

That’s why the likes of Miju Precision, Imflux, MI Integration, Changyoung Precision, and LG Electronics, trust Vericut to deliver safer machining and better molds.

And because every mold ultimately drives high-volume production — whether in automotive, medical, or other essential markets — Vericut’s role goes far beyond the machine shop floor.

By enabling defect-free, optimized molds, it safeguards the efficiency, quality, and reliability of the entire injection molding operations.

Every mold is a one-off tool that directly impacts thousands of downstream products. Simulation ensures that machining is safe, accurate, and efficient before making a single cut — reducing scrap, rework, and delays.

Absolutely. Vericut validates toolpaths directly from the NC code, not just CAM previews. This means it can simulate long, intricate 5-axis or multi-axis programs with complete accuracy, preventing collisions, overtravel, or gouging.

It is indeed. Vericut scales from independent toolmakers to global manufacturers. Even smaller shops benefit from reduced scrap, safer machining, and shorter lead times — without needing to invest in additional machine trials.

With its Die Sinking EDM simulation, Vericut validates electrode geometry, checks for gouges and remaining material, and reduces the number of electrodes needed. This saves cost, simplifies workflows, and shortens lead times.

The most immediate ROI is reduced machining time — often visible after the first test run. Shops also report improved delivery reliability, fewer scrapped parts, lower tool costs, and even reduced energy consumption.

It can. By controlling cutting forces and vibration in advance, Vericut Force optimization helps shops maintain tight tolerances and deliver consistent, high-quality surface finishes — critical for molds used in plastic injection molding.

Vericut works alongside all major CAM software, importing the NC program for verification. Because it simulates the actual G-code, it catches errors that CAM systems alone cannot — such as controller-specific behaviors, feed rate miscalculations, or machine kinematics.

See how Vericut CNC simulation software can help your business forgo its CNC machining frustrations.

Address:

Vericut USA

CGTech Corporate Headquarters

9000 Research Drive

Irvine, California

92618-4214

Phone:

(949) 753-1050