Virtual CNC software enables automotive manufacturers to simulate and optimize machining processes before physical production commences. By digitally modeling components and simulating machining operations, errors are minimized, lead times reduced, and resource utilization optimized, bolstering productivity and cost-effectiveness. This technology fosters innovation in product design and customization. With rapid prototyping and iterative design capabilities, manufacturers can explore new concepts swiftly.

Additionally, through realistic simulations of machining operations, operators and engineers can enhance their skills in a safe, controlled environment, eliminating the need for costly physical prototypes or machine time.

As the automotive industry evolves, integrating virtual CNC software becomes a strategic imperative for manufacturers. By embracing this technology, companies can unlock new avenues for growth, efficiency, and innovation.

The automotive industry has been through major changes and those that have survived have been prepared and adaptable. The more recent shift towards electric vehicles, plus the future outlook on more autonomous vehicles, come with great challenges for the industry.

Alongside other priorities, the goal of energy-efficient manufacturing – reducing energy consumption and increasing sustainability – is at the forefront for all manufacturing businesses. In order to rise to the challenges, automotive manufacturers need to redistribute their budgets quickly and in a targeted manner. Research and development need to focus on software and on manufacturing feasibility. The software needs to enhance the performance of the products while keeping costs down.

Focusing primarily on processes, rather than on individual machines, systems, or functions. Even in a downturn scenario, fast, decisive action on investments in the next technological generation for better workflows must not be taken for granted.

Of course, the possibilities of smart alternatives in automotive manufacturing are based primarily on stringent digitization. It is not for nothing that NC simulation is considered a lighthouse project and early mover among the digital game changers as the interface between CAM programming, work preparation, and the shopfloor.

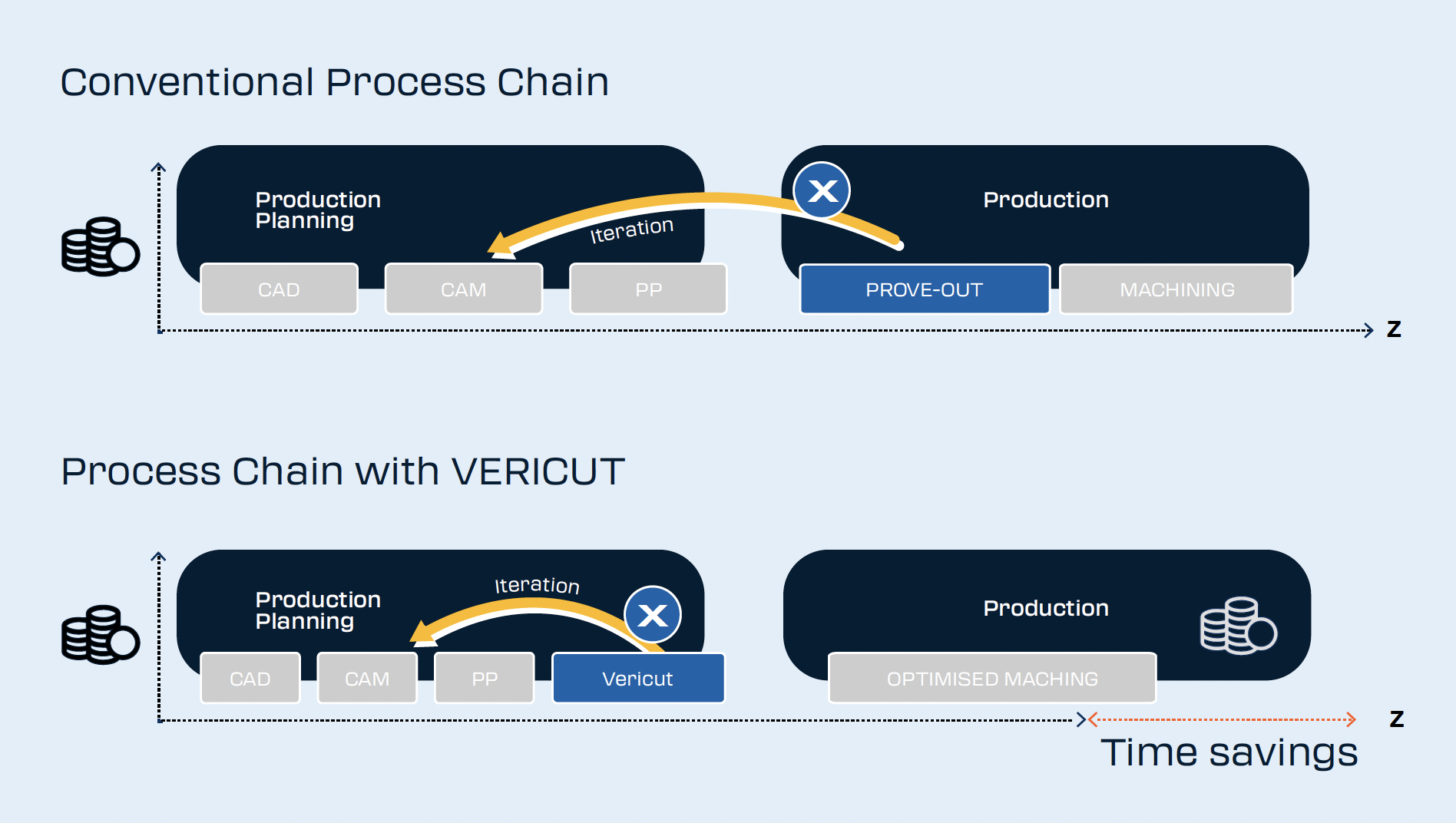

Manufacturing simulation of the NC data, i.e., the machine code, addresses the really important fields of action in metal-cutting manufacturing: safe prove-outs of complex clamping situations, manufacturing without scrap, machining without machine collisions, increasing tool life, faster NC programs with reduced machining times and improved part quality.

To be resilient and prepared automotive manufacturers must be responsive and adaptable, which requires a keen awareness of any issues, disruptions and challenges that may arise. Creating high quality machined parts, in the least amount of time, and at the lowest possible cost will always be the biggest challenge.

No one can accurately predict the future in its entirety. Environmental and economical conditions are too complex for that, and so are a company’s own systems in most cases. To lessen the impact of supply shortages, a starting point is to purchase materials from reputable and reliable suppliers and, where and when feasible, define alternate manufacturing plans such as using different CNC machines or begin with plate stock instead of castings/forgings. Software is indispensable as it can track and optimize.

Disruptions in the supply chain can be disastrous and lead to detrimental consequences affecting part costs and/or scheduled manufacturing plans. When materials necessary for machine part fabrication become delayed or unavailable, materials will have to be sourced under short notice, which will come at higher purchase and delivery costs. In some cases, part fabrication plans need to be modified or redone from scratch in order to work with what is available, rather than what was originally intended.

There are a couple of dominating challenges for making CNC machined automative parts, the first being consistent part accuracy. It often isn’t feasible to check every part made, inspection procedures usually check a representative part for a specified lot quantity.

But if other “bad” parts are later identified, this can cause problems in assemblies where the part is used, disrupt assembly lines, lead to a bad supplier reputation, or even cancelled contracts.

The second challenge is part surface quality, especially for automotive tooling such as body panel molds and dies. CNC-machined molds and dies take a substantial amount of time to create, and planners must account for that in scheduling.

Reducing costs and operating more efficiently are both key in ensuring that automotive manufacturers remain resilient and competitive. Manufacturing technology can aid resource planning, monitor shop throughput and increase automation. In addition, taking advantage of advanced manufacturing software that can optimize NC programming strategies, and NC program feeds and speeds per cutting tools allows manufacturers to achieve previously unobtainable levels of machining optimization, and increase part quality.

The drive for high quality and high volume will remain key to the industry, and cycle time – cost, seconds and pennies – will always be a concern. The move towards hybrid vehicles continues to rapidly pick up pace and plug-in hybrids are becoming even more popular. The future is battery electric or fuel-cell electric vehicles, referred to as NEV – New Electric Vehicles..

These changes in the automotive industry require new types of components, including electric motor housings, new types of gear housings, new examples of covers and all accessories related to E-mobility. There will be increased demand for retooling, new tooling and processes to produce these components.

Manufacturers face a whole series of problems that intersect between CNC programming, planning, and production. Below is a summary of these challenges:

Safety-critical components economic consideration.

Demand for safe, reliable, and high-quality processes.

Scrap and collisions versus high raw material and energy prices; delivery timelines; small profit margins.

Integration of state-of-the-art technology during operation.

Prompt return on investment even with small quantities; sustainability in financial & operational strategies.

Increased fluctuation, higher illness rates, lower motivation due to performance pressure and changing generations on the shop floor.

Based on the digital twin of machine, workpiece and machining process, the potential offered by the visualisation of future processes is to be developed.

Proactive reduction of later operating costs.

Traceability of the product lifecycle for maintenance, material recycling

Margin pressures especially when mitigating supply chain disruptions and shortages alongside fluctuations in demand.

Timely delivery of safetycritical products.

Prerequisites for industry 4.0 with artificial intelligence, machine learning, augmented reality, predictive maintenance etc.

High spare parts costs, expensive downtime, loss of earnings, loss of reputation.

Production and plant management need consistent data as a basis for planning.

Necessity to reduce production latency times.

High raw material costs, short tool life, managing chip thickness, loss of earnings, loss of reputation.

More problematic with longer cycle run times.

High cost of spare parts, expensive downtime, loss of earnings, loss of reputation.

Have room for agility during order peaks without buying additional machines.

Required for lower expenses (time, personnel, spare parts etc.)

Reduce orders lost due to quality issues or slow time-to-market.

Potential disruptions in the supply chain, such as those caused by geopolitical tensions or natural disasters, can lead to price fluctuation and shortages. Anticipating these disruptions can mean successfully mitigating potentially fragile manufacturing situations and maintaining stable operations.

Tip: Beyond the typical corporate activities to counter impending supply problems, companies must achieve new levels of internal efficiency to address the need for materials and energy. Focus is on planning production efficiently from the start, and digital solutions that combine both quality assurance with autonomous production control will increase the resource efficiency of manufacturing processes.

With the rapid advancement in technologies like electric vehicles and autonomous driving systems, manufacturing processes must remain adaptable and flexible to incorporate these changes quickly and efficiently. Investments in new initiatives and technology adoption within manufacturing facilities.

Tip: Changes in the automotive industry will require new types of components, tooling and processes. High volume will remain key to the industry, and any mistakes can be costly. Consider the production environment – the machines, their automation, the required floor space, raw materials and invested capital – and the initial information required for accurate process planning – machining operations, required tools, the cycle time, production rate and requirements.

Politically intended and socially approved, sustainability is an obvious and logical goal. Companies often see it as their duty to implement the principle and practice of sustainability. If done correctly, specific measures can be positioned within manufacturing processes and product design to reduce environmental impact and to comply with regulatory standards.

Tip: To minimize the CO2 footprint, for example, companies will want to use raw materials and energy efficiently. Quickly digitizing defined manufacturing segments is a good example, reducing the material used, energy spent, and time wasted on manual prove-outs.

Safely testing and producing any parts in a virtual environment often negates the need to physically test run, or prove-out, a part prior to production, which removes the chances of scrapping (wasting) raw material to generate an erroneous part, along with chance that the NC program might contain errors that could cause the machine tool to crash and become damaged.

Optimizing the NC code to produce a more efficient program results in manufacturing cycle time savings of between 10% and 40%, depending upon the raw material and complexity of the parts. The savings from wasted time and power consumed are significant.

Maintaining product quality and safety is crucial in the automotive industry. Having quality control measures and protocols in place throughout the manufacturing process to identify defects or issues early on is essential to production schedules, cost control and customer satisfaction.

Tip: Every step in the process – engineering, design, CAM programming and machining – should be inspected, verified and optimized. Simulation and verification technology ensures programs are error free and all operations work together as intended, and optimization ensures the whole process is operating as efficiently as possible to save time and money.

Continuous development of the workforce and improving their skills will increase productivity, improve the quality of work, and reduce faults, waste or customer complaints. As industry and manufacturing technologies evolve, so too should the workforce.

Tip: There is no denying that skilled machinists are hard to come by. With a large percentage of the current workforce of NC programmers and machinists getting ready to retire and a shortage of newly qualified engineering talent, finding people to work in this industry and fill the void is becoming increasingly more difficult.

Software can provide a large amount of data and information that can be used to improve the manufacturing workflow and free up a skilled machinist’s time.

Engineering companies are now facing the challenge of meeting increased demands and staying competitive with fewer programmers and machinists. Working smarter with software reduces the need to fill all those voids.

CNC simulation software can verify a part, simulate the machining and optimize the NC code before any real machining has started. Therefore, making unattended or lights out machining, and the ability to operate with less machinists, a reality.

Wherever milling, drilling or turning is done based on NC programs, NC simulation tools simulate the original NC code after the post-processing. Checking and optimizing toolpaths are among the best practices for manufacturing optimization.

For users, the only sure way is to simulate an actual machining situation with a “virtual machine tool on the desk”. Ideally, NC simulation works independently of the CAM programming system, CNC machine, and controls.

Special benefits for automotive

Independence promotes connectivity. This is particularly advantageous in manufacturing environments with a wide range of machines, systems and software.

The simulation, verification, and optimization of CNC machines allows for reliable planning by virtually mapping future processes in the present and eliminating potential errors in the NC program before physically machining a workpiece.

Special benefits for automotive

Shorter cycle times and safe prove-outs are critically important. Increased tool life, reduced tool breakage, no damaged fixtures, and no machine collisions are practical investments.

NC simulation creates a sense of certainty for production planning through the precise determination of manufacturing times. This makes it easier to optimize traditionally sequential workflows in metal-cutting production and opens up the ability to run parallel projects. Simulation allows for better machine utilization, employee relief from routine tasks and program rework, and fewer delays or rescheduling of production plans.

Special benefits for automotive

The current shortage of skilled workers and higher sickness rates are critical in an already tense market environment. In the face of shifting market trends, changes to customer demands, unprecedented stringent quality requirements, and the growing use of new technology, adequate employee motivation and resource management are of utmost importance in sectors where producing high quality machined parts, in the least amount of time, and at the lowest possible cost is the primary goal.

The industry is under enormous pressure to innovate, but this requires a balanced approach in financial and operational strategies. Implementing and utilizing new technologies, new materials, and new manufacturing processes can pose large challenges for companies, especially mid-sized suppliers. Companies that also operate outside the automotive industry often have to carefully weigh whether the quantities they produce within the industry justify the high costs associated with these new investments.

Nearly every budget set aside for innovation is the subject of intense discussion. An investment in NC simulation, however, is typically out of the question. A rough calculation of the return on investment with NC simulation is extraordinary and can be paid back in as short a time as machining a single workpiece. NC simulation has been used since the 1980s, utilizing digital twins of the CNC machine, workpiece, and the NC program, making it one of the main players and a key investment in today’s Industry 4.0 initiatives.

.jpg?width=940&height=1085&name=Frame%2048095836%20(1).jpg)

Avoid machine collisions

Safe prove-outs, even with complex clamping setups

Reduce prove-out times

Increase tool life

Faster NC programs

Improved part quality

Reduced machining times

Detect differences between design model & simulated part

Increased machine capacities

Problem-free setup of new parts

Avoidance of scrap

No rework, schedule deviations, or delivery delays

Reduced stress level

Relief of employees

Protect expensive production equipment

Reduce production costs

Easy integration into digital ecosystems

Verciut Force doesn’t just help eliminate errors; it also provides huge savings in machining time. It’s a vital tool for modern-day automotive manufacturers on the hunt for a competitive edge.