When applying composite materials, preserving those expensive materials and limiting unnecessary waste are mission-critical.

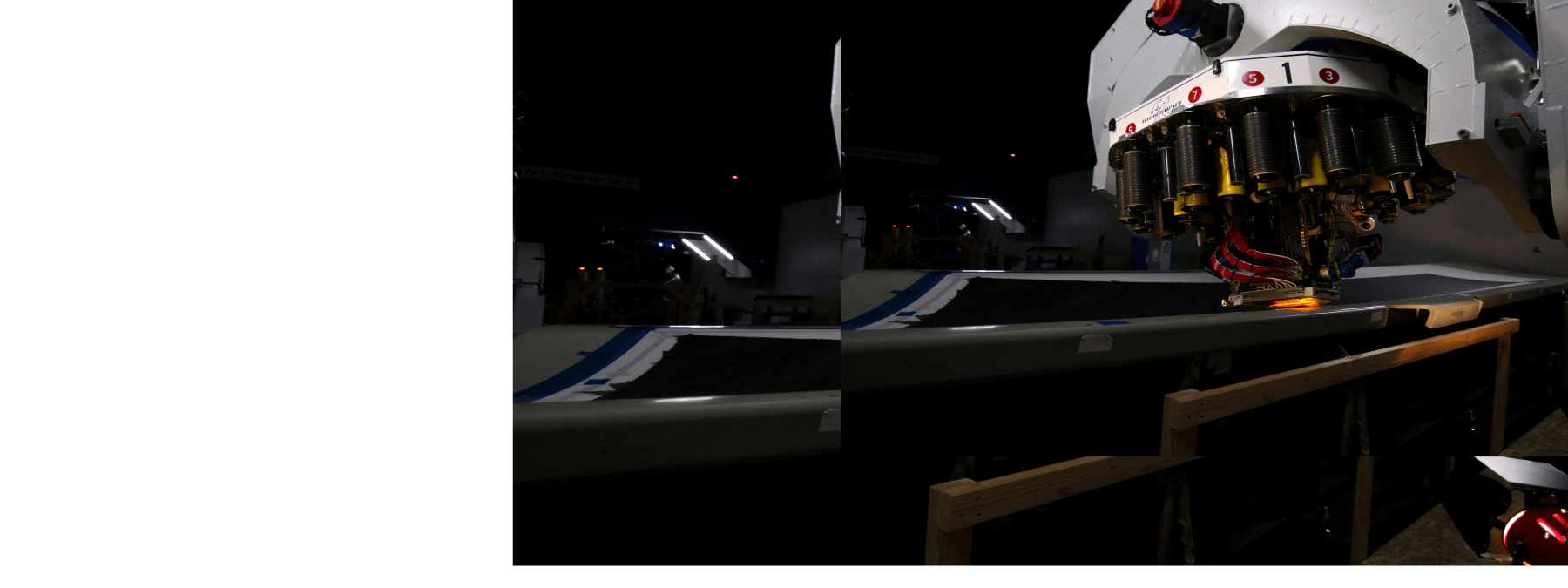

With Vericut Composites Simulation (VCS), manufacturers across the UK can free their production of costly mishaps by accurately simulating their work environments and NC programs for automated composite applications.

With Vericut Composites Simulation (VCS), manufacturers can read, validate, and simulate the NC programs that will run on the layup equipment. VCS is capable of simulating upwards of 500 individual composite fibre layers, too.

VCS empowers manufacturers by expertly verifying the process for compaction roller, form conformance, and direction - analysing orientation, path correctness, layering sequences, and compaction axis travel.

If additional material needs to be added, VCS can precisely measure and inspect it. This extra level of accuracy makes sure the newly-layered composite part is free from overlaps, gap areas, or other defects which could result in a faulty run, or a crashed machine.

The Vericut Composites Simulation (VCS) module helps UK manufacturers confidently fulfil contracts with unrivalled precision.

Vericut saved us €30,000.00 on one part alone!

Detect errors, eliminate collisions and say goodbye to manual prove-outs once and for all.

Optimise your tool paths and enhance your NC programs for the fastest, most efficient machines, ever.

Compare CAD design modules to Vericut simulations and detect design differences and weaknesses.

Verify complex multi-axis machine applications and check for errors at the workpiece and the tool.

Create and manage your most accurate digital twins ever by leveraging CNC machine data from your shop floor.

See how Vericut CNC simulation software helps UK manufacturing businesses like yours forgo CNC machining frustrations.

Address:

Vericut UK

Curtis House, 34 Third Avenue,

Hove, East Sussex, BN3 2PD

Phone:

+44 (0)1273-773538