The CNC machines on your shop floor are packed with valuable data and insights.

Vericut’s CNC Machine Connect and CNC Machine Monitoring modules leverage that data to help manufacturers optimize machining performance and productivity.

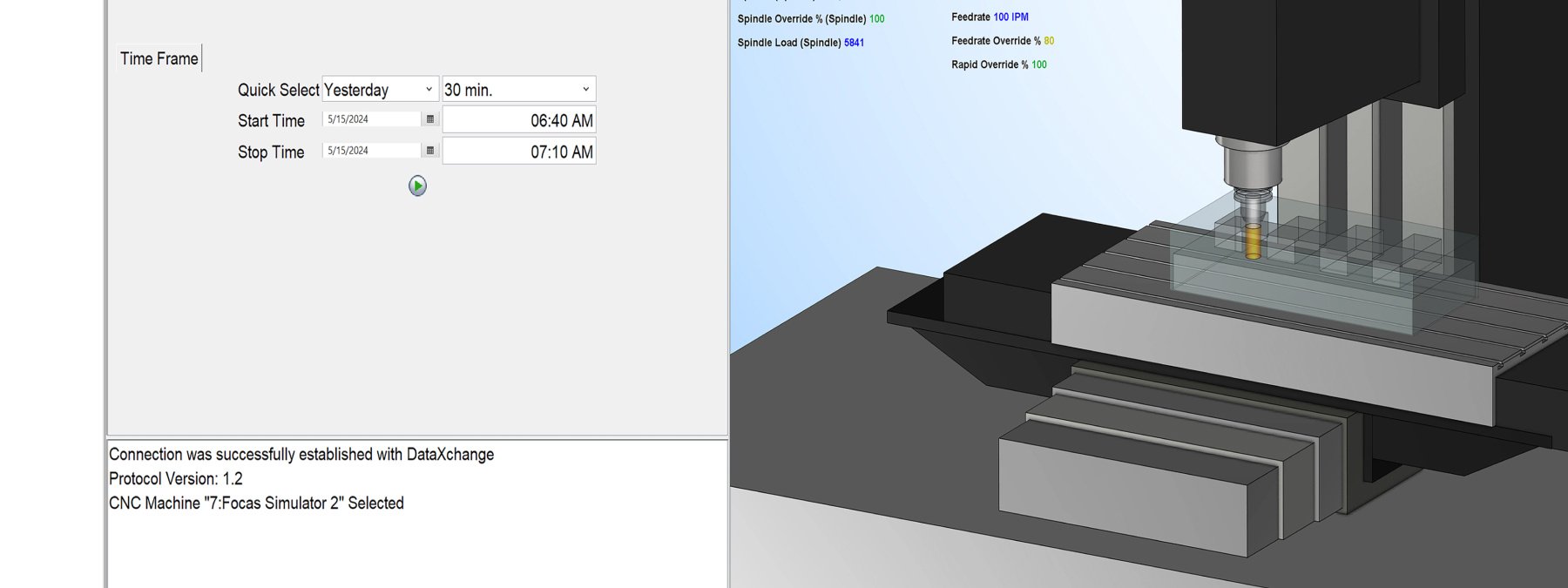

With Vericut CNC Machine Connect, users can access and utilize their machine’s data, while CNC Machine Monitoring software allows them to track and live-stream the data in real time. When combined, they create the most robust and highly accurate digital twins ever.

The Vericut CNC Machine Connect module allows manufacturers to ensure that all machine setups (including fixtures, stock, offsets, and NC programs) align with the Vericut simulation. If there’s any discrepancy, they’ll be promptly notified.

With Vericut CNC Machine Monitoring, manufacturers can easily assess their machine’s feed rate, spindle utilization, programming, and overall status, all through simple color-coded signal lights (Green, Yellow, Orange, and Red).

Ever wanted to monitor all your machines’ behaviors and functions while away from the shop floor? Now you can. CNC Machine Monitoring boosts visibility and provides users with the confidence to make the most informed machining decisions every time.

With the Vericut CNC Machine Connect and Monitoring modules, manufacturers can harness the power of Postcheck to quickly access past machining data. Postcheck retrieves and reviews archived data from your machine in Vericut, helping you identify any discrepancies that may have occurred during the machining process.

Integrate the Vericut CNC Machine Connect and CNC Machine Monitoring modules with your Vericut CNC simulation software, and use shop floor data to make the most informed machining decisions.

The biggest advantage of Vericut has been out on the shop floor. During tests, the department figured it saved 30% in machine run time on graphite electrode machining, and we’ve seen up to 45% machine run time savings in some cases.

Identify errors, prevent collisions, and eliminate manual prove-outs for good.

Optimize your tool paths and refine your NC programs for the fastest, most efficient machining performance yet.

Compare CAD design modules to Vericut simulations and detect design differences and weaknesses.

Verify complex multi-axis machining operations and check for errors both at the workpiece and the tool.

Conduct realistic 3D simulations of entire CNC machines, reflecting their actual behavior in the shop, with the most precise collision detection available.

Discover how Vericut CNC simulation software can help your business overcome CNC machining challenges.

Address:

Vericut India

CGTech India

BLOOMING CO-WORKING SPACES

No. 9/36, Vaishnavi Sapphire Centre

2nd Floor, Tumkur Road, Yeshawanthpur,

Bangalore – 560022 , Karnataka

Phone:

+91- 91084 04780